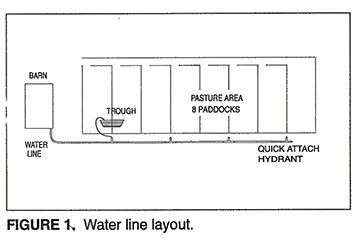

These water lines can be buried at a shallow depth to protect them from machinery, cattle, and the sun. Due to its strength, high pressure pipe is usually used to prevent collapse or other damage. Water in pipes exposed to the sun can become fairly hot. Available now, are UV-protected white plastic lines which reduce heating. However, heating of water in black plastic lines is not of great concern since vegetation establishes quickly over the water line. For convenience though, the main pipeline should be buried after farmers are satisfied with the layout.

Quick attach hydrants and portable troughs (180 L, 40 gal) are becoming popular. These small troughs must be equipped with full flow or high output valves since traditional float valves often do not allow sufficient output. Rapid water recovery is the key to making small troughs work. It is also important to install them near the grazing cattle so that they do not all move together as a group for water.

This system is easy to install and very reliable. Water lines need to be drained in the fall to avoid damage due to freezing.

Gravity Fed System

Although gravity fed watering systems have been supplying fresh water to many households in Atlantic Canada, not many systems are installed to water grazing cattle. This low cost system can be easily installed to provide water for cattle where there is sufficient grade to allow a gravity flow. Springs are the most common water sources used.

It is essential to determine both the capacity of the water supply and the difference in elevation between the water source and the proposed watering area. To prevent the occurrence of airlocks, the water line should be laid on a uniform grade. To minimize flow resistance, a pipe diameter of 32 mm (11/4") should be used for grades over 1.0%; for grades from 1.0% down to 0.5% a 38 mm (111/2") line is recommended. For grades less than 0.2%, gravity systems should not be used.

Watering troughs can be equipped with float valves or with an overflow mechanism. When installed correctly, gravity fed systems are very reliable and require minimal maintenance.

Pasture Pump

The pasture pump (nose pump) is livestock operated. The apparatus is activated by cattle when they push and release a lever with their muzzle. This action pumps and allows the water to enter the pump's basin. The system requires a 25 mm (1 ") line and a foot valve.

To train cattle, exclude or remove all other water sources from the pasture and, if possible, install the pump near the previous watering area. The pump must be level so that the water does not run out of the basin. It must also be well secured so that cattle do not push it around. Cattle generally learn to use it quickly and with no difficulties.

Water can be drawn from springs, streams, ponds, or shallow wells. One pump is sufficient for 20 to 30 head of cattle, depending on pasture design. When cattle travel long distances for water, they tend to travel in groups. Since the pasture pump can only supply water to one animal at a time, problems can result.

The pasture pump can be relocated quickly and easily. For small herds this is a cost-effective watering system.

Hydraulic Ram Pump

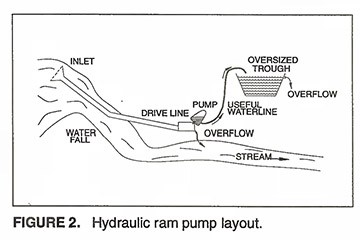

Ram pumps are not new technology. In fact, these pumps were first used in the late 1770's. There are many types of hydraulic ram pumps on the market today. Although they all use the force of falling water as their source of energy, they vary substantially in their design, construction materials, and capacity.

These self-activated pumps are generally set beside or in a shallow stream, located below the water intake. The pressure generated by the failing water entering the pump, compresses air in a surge tank which, subsequently, is used to push a portion of the water uphill to where it is needed. These bursts of compression are of very short duration, 25 to 100 compression per minute.

Once the system is operational and well tuned, it will supply a continuous flow of water To allow for proper tuning, it is essential that the unit be installed as specified by the manufacturers. Additional components such as valves and a stand pipe may be necessary.